About Me

Hi, I'm Akash, a Mechanical Engineer passionate about innovative design and product development.

I specialize in CAD modeling, stress analysis, and the integration of engineering solutions. I've worked on diverse and impactful projects, including the development of 60-ton friction welding machines and compact 4x4-inch ceiling antennas. My experience spans multiple industries, such as automotive, aerospace, and defense, where I focus on delivering high performance, reliability, and manufacturability in every design.

Outside of work, I enjoy traveling, caring for house plants, watching reruns of The Office, and playing Zelda on my Switch.

Experience

-

Friction Welding Technologies

Mechanical EngineerJan 2022 - Dec 2022At Friction Welding Technologies, I led the design and development of 60-ton friction welding machines (valued at $350,000) for the automotive, aerospace, and defense sectors. My role involved managing the entire project lifecycle from concept to assembly, using SolidWorks and AutoCAD for precise modeling and ANSYS for Finite Element Analysis (FEA) to ensure structural integrity. I applied Design for Manufacture & Assembly (DFMA) and GD&T to optimize parts for manufacturability and reduce costs. I also oversaw the fabrication of CNC and sheet metal components, incorporating feedback from cross-functional teams to enhance design and reliability.

- Project Management

- SolidWorks

- AutoCAD

- ANSYS

- GD&T

- DFMA

- FMEA

- CNC

- Sheet Metal

-

JMA Wireless

Mechanical EngineerJun 2020 - May 2021At JMA Wireless, I was responsible for the design and development of small-scale antennas, including ceiling and stadium antennas. I utilized SolidWorks for precise electromechanical packaging and integrated 3D printing for rapid prototyping, which significantly shortened the product development cycle. I conducted thorough RF performance testing using Six Sigma methodologies, refining signal quality and reliability. Additionally, I created custom sheet-metal mounting solutions tailored to specific installation requirements, streamlining the implementation process across various venues.

- Product Development

- SolidWorks

- SAP

- Six Sigma

- Root Cause Analysis

- 3D Printing

- Sheet Metal

- Injection Molding

Education

-

Carnegie Mellon University

Master of Science, Mechanical EngineeringJan 2023 - May 2024 -

University at Buffalo

Bachelor of Science, Mechanical and Aerospace EngineeringAug 2016 - May 2020

Projects

-

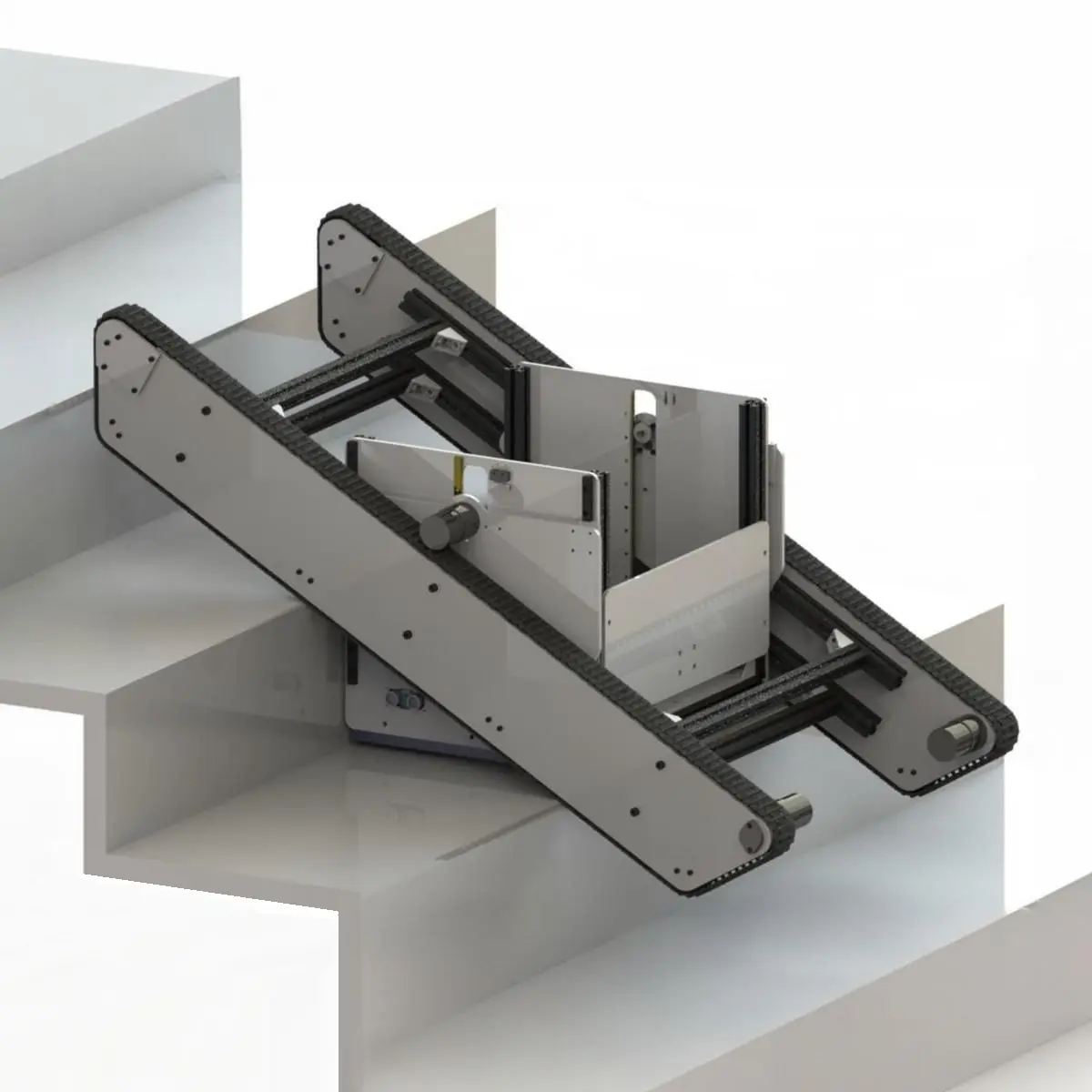

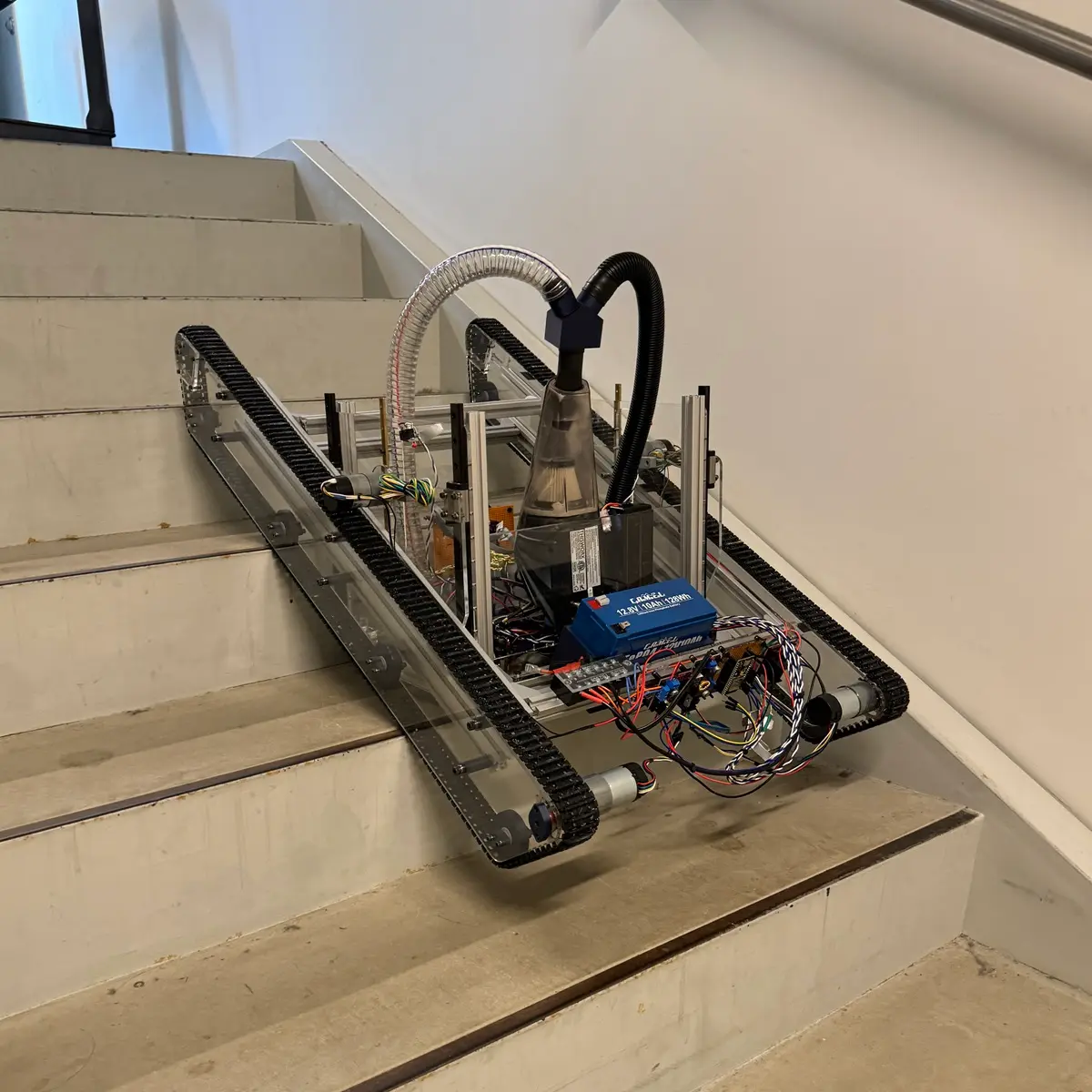

Stair-Vacuum Robot

Carnegie Mellon UniversityJan 2024 - Apr 2024As the lead mechanical engineer on a team project, I developed and designed an autonomous stair-cleaning robot. I handled all aspects of the mechanical design, utilizing PTC Creo to create a robust tank-tread system that enhanced stability and maneuverability across various stair types. I engineered the central vacuum box for optimal debris collection and integrated advanced sensors and microcontrollers for autonomous operation. I personally executed the prototyping phase, using 3D printing, laser cutting, and machining techniques to fabricate components and ensure precision in manufacturing and assembly. Conducted rigorous testing to validate the robot's performance, reliability, and adaptability, focusing on manufacturing efficiency and ease of assembly.

Initial Tread Design

Final CAD Model

First Prototype

- PTC Creo

- Python

- Arduino

- Laser Cutting

- 3D Printing

- Machining

-

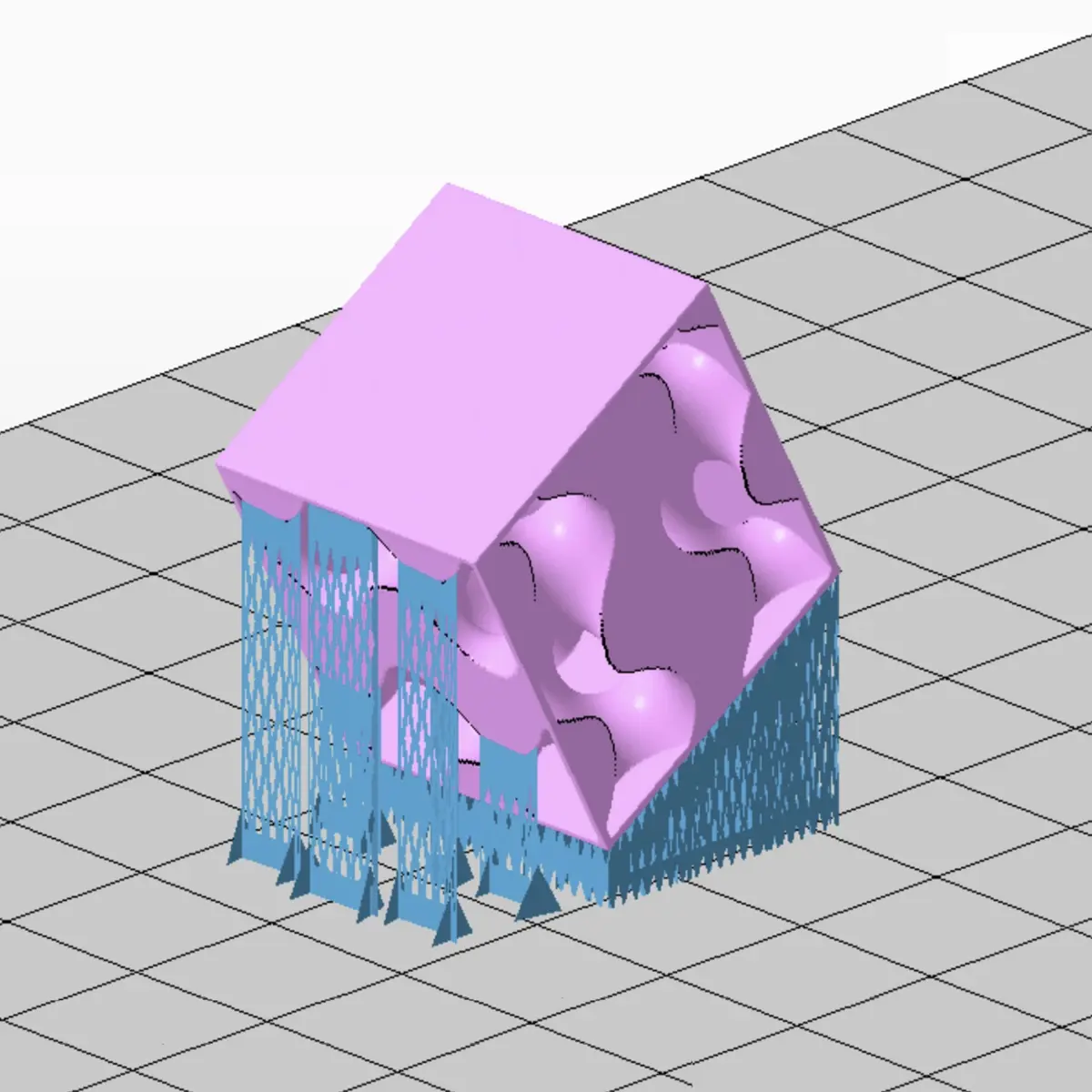

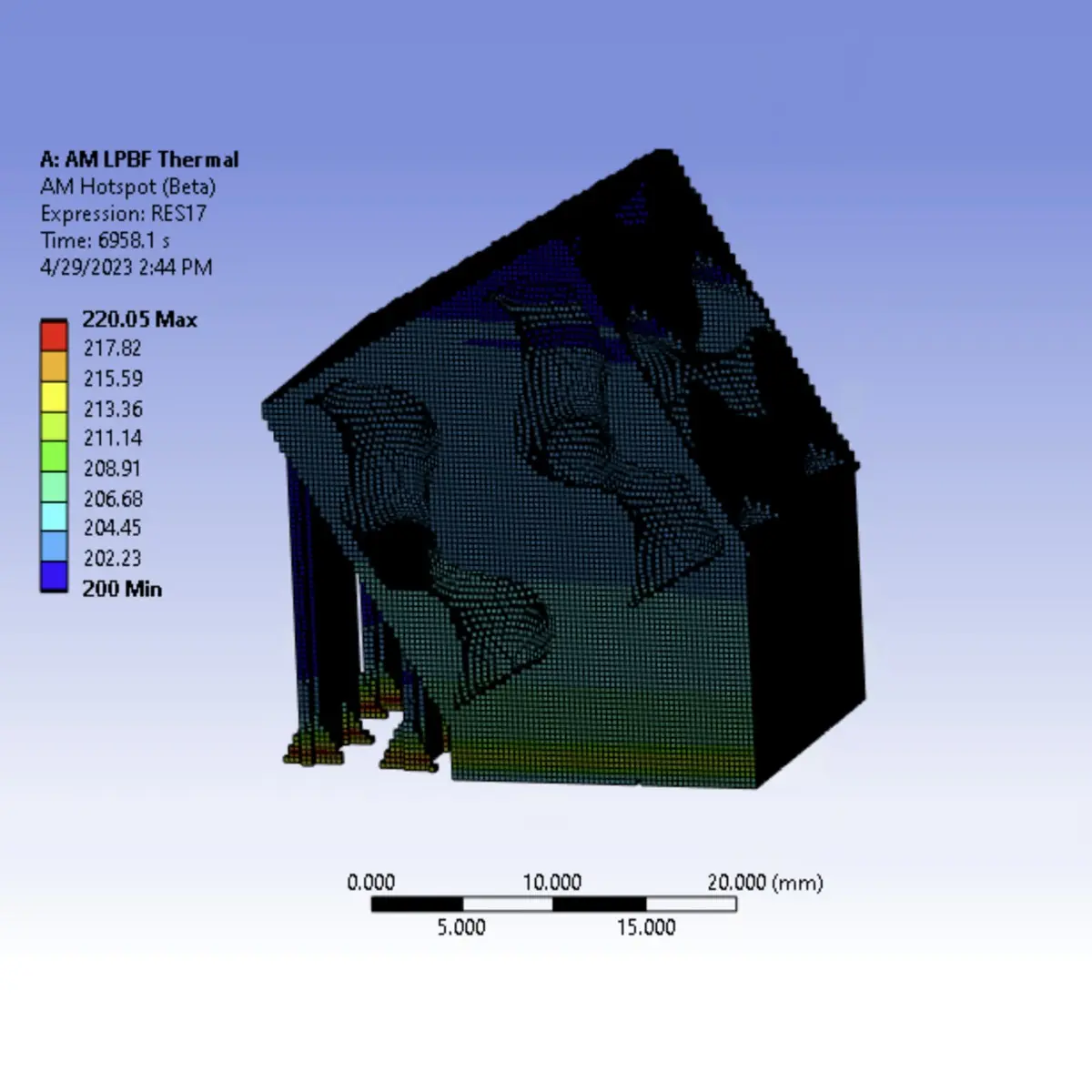

High-Efficiency Heat Exchanger

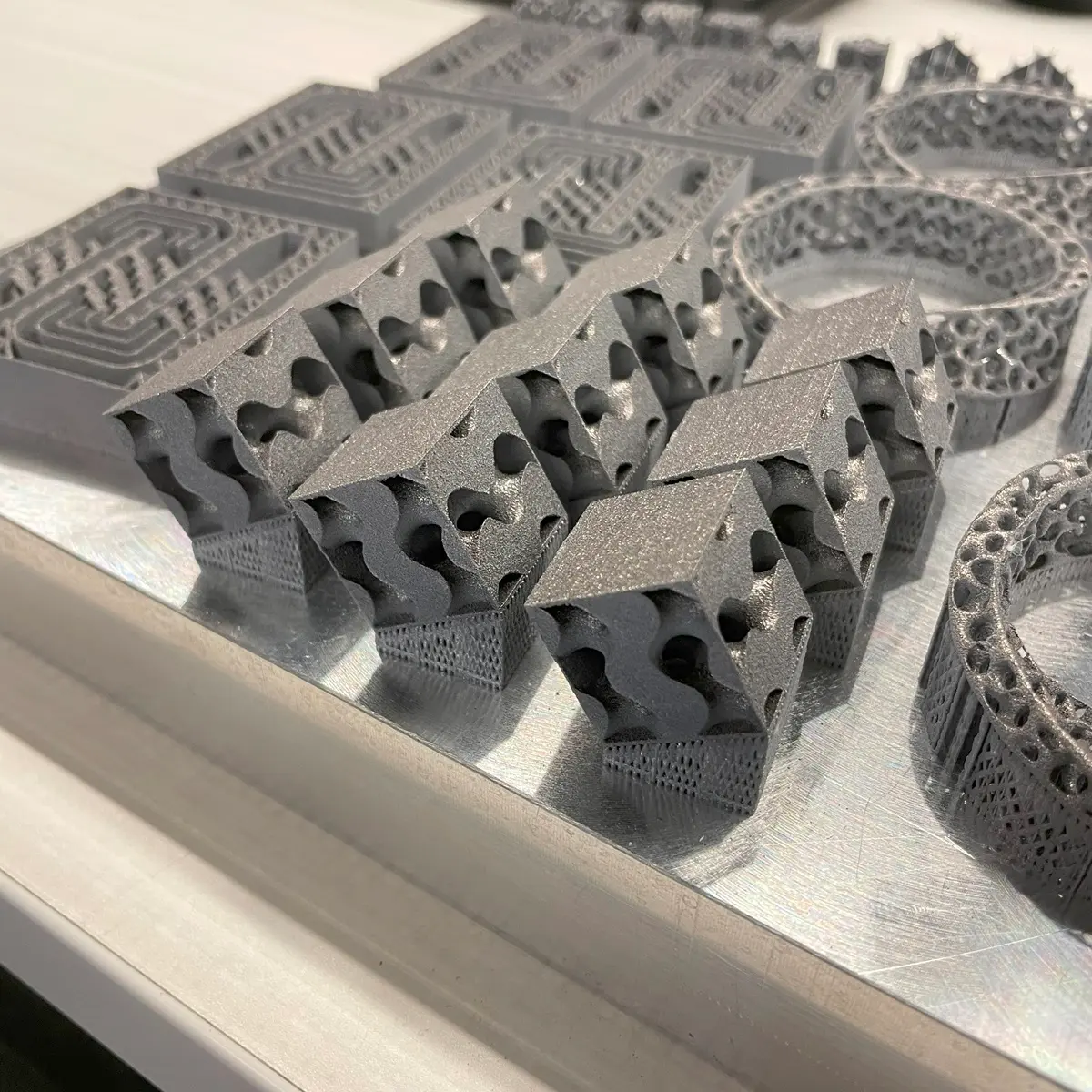

Carnegie Mellon UniversityJan 2023 - Apr 2023As part of a team, I was responsible for developing a high-efficiency heat exchanger for high-performance vehicles using additive manufacturing techniques. Focusing on optimizing thermal performance, I utilized gyroid structures to maximize surface area for heat transfer while minimizing material usage. I designed the complex geometries in PTC Creo and performed CFD simulations using ANSYS Fluent to evaluate temperature and pressure distribution. The project aimed to reduce drag and enhance cooling efficiency, making the heat exchanger both lightweight and compact for racing applications. My role also involved refining the manufacturing process, utilizing 3D printing to produce prototypes that significantly improved thermal management and reduced the overall size of the cooling systems.

Initial Design

Thermal Simulation

Test Prints

- PTC Creo

- ANSYS

- CFD

- Rapid Prototyping

- Additive Manufacturing

- 3D Printing

-

Product Data Management

Friction Welding TechnologiesOct 2022 - Dec 2022I led the transition of over 1,000 legacy CAD models from the company server to the EPDM system, fully integrating it with SolidWorks. I developed a comprehensive hardware library within EPDM to streamline workflows, enhance usability, and facilitate the reuse of project files. This upgrade improved efficiency by simplifying file access, reducing redundant work, and saving significant server space. This system improved efficiency by simplifying file access, reducing redundant work, and setting a new standard for project management within the company.

- Project Management

- SolidWorks

- EPDM

-

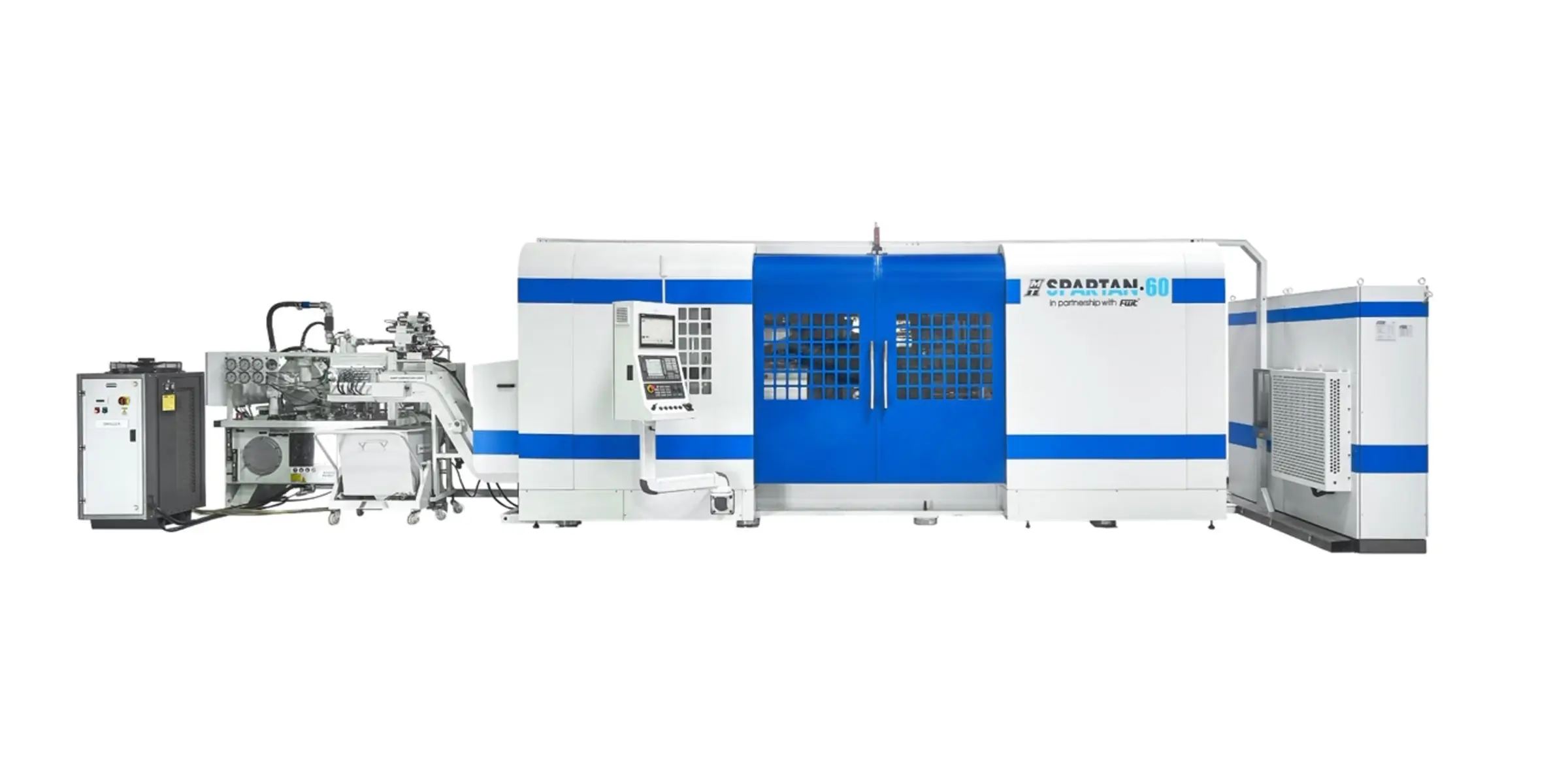

Friction Welding Machine

Friction Welding TechnologiesJan 2022 - Sep 2022I led the design and development of a $350,000, 60-ton friction welding machine, managing the entire project lifecycle from concept to assembly. Utilizing SolidWorks and AutoCAD, I performed detailed modeling and design of sheet metal, cast, and machined parts. I conducted ANSYS simulations to optimize the structural integrity of the machine and implemented Failure Mode and Effects Analysis (FMEA) to identify potential failure modes and mitigate risks. I also included safety features such as proximity sensors on doors and emergency stop buttons to enhance operational safety. Additionally, I designed a new CNC user operator manual with a sheet metal casing. My role involved overseeing the integration of mechanical, electronic, and pneumatic systems, ensuring seamless operation and compliance with quality standards.

Friction Welding Machine

Operator Console

- Project Management

- SolidWorks

- AutoCAD

- ANSYS

- DFMA

- GD&T

- FMEA

-

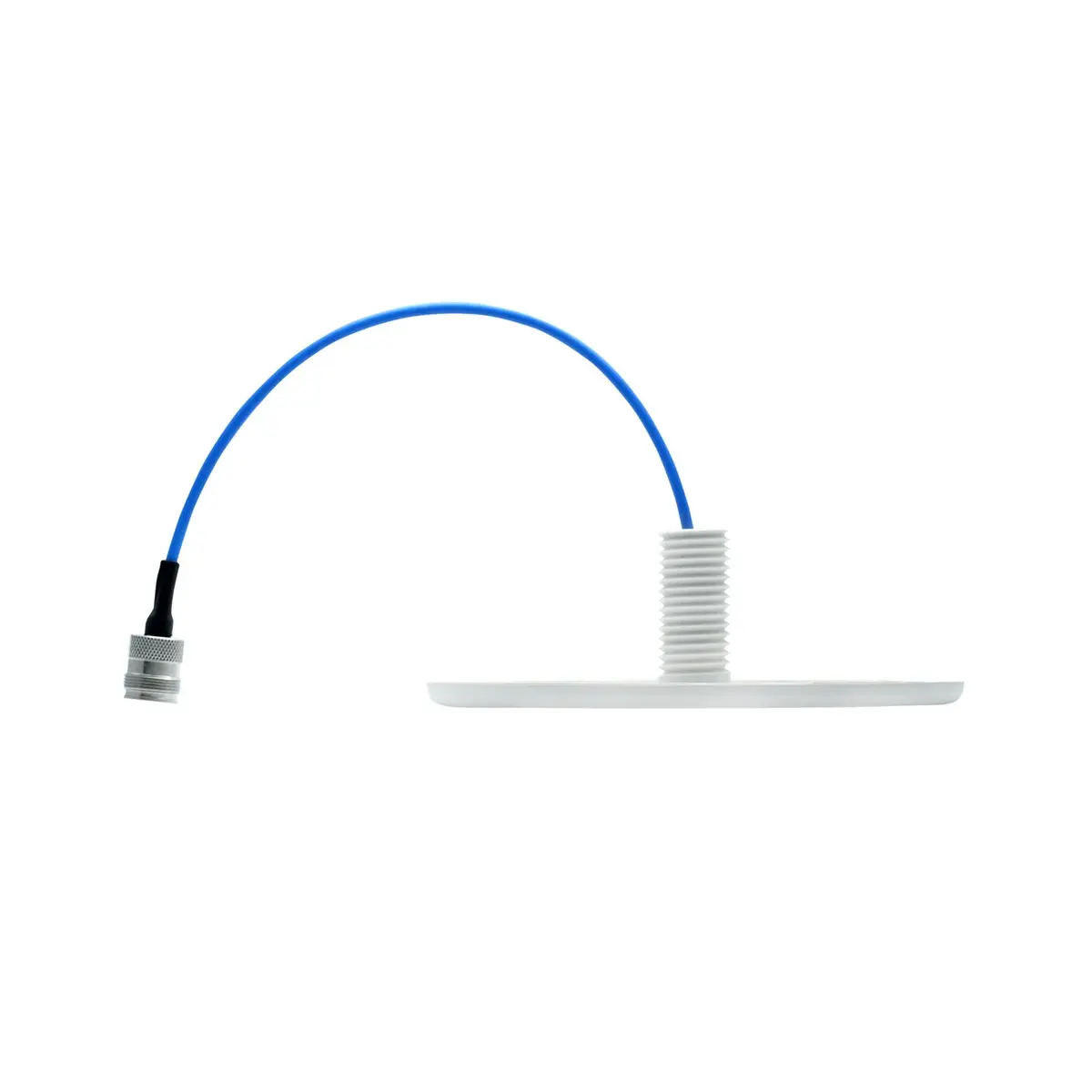

Compact Ceiling Antenna

JMA WirelessOct 2020 - Dec 2020I designed a compact, 4x4-inch omnidirectional antenna using SolidWorks, optimizing RF performance and manufacturability with Design for Manufacturing and Ease of Assembly (DFMA) principles. The antenna's design required only two injection-molded casings and two PCBs, which were securely held in place with snap-fit features, eliminating the need for additional hardware. The entire assembly could be installed through a single hole in any office ceiling tile, simplifying installation. I used resin 3D printing for rapid prototyping to refine the snap-fit features and ensure precise PCB integration before transitioning to injection molding. ANSYS simulations were conducted to ensure optimal signal quality and performance, making it a reliable and efficient solution for in-building communication.

Example Design 1

Example Design 2

Mounted on Ceiling Tile

- Product Development

- SolidWorks

- ANSYS

- DFMA

- 3D Printing

- Injection Molding

-

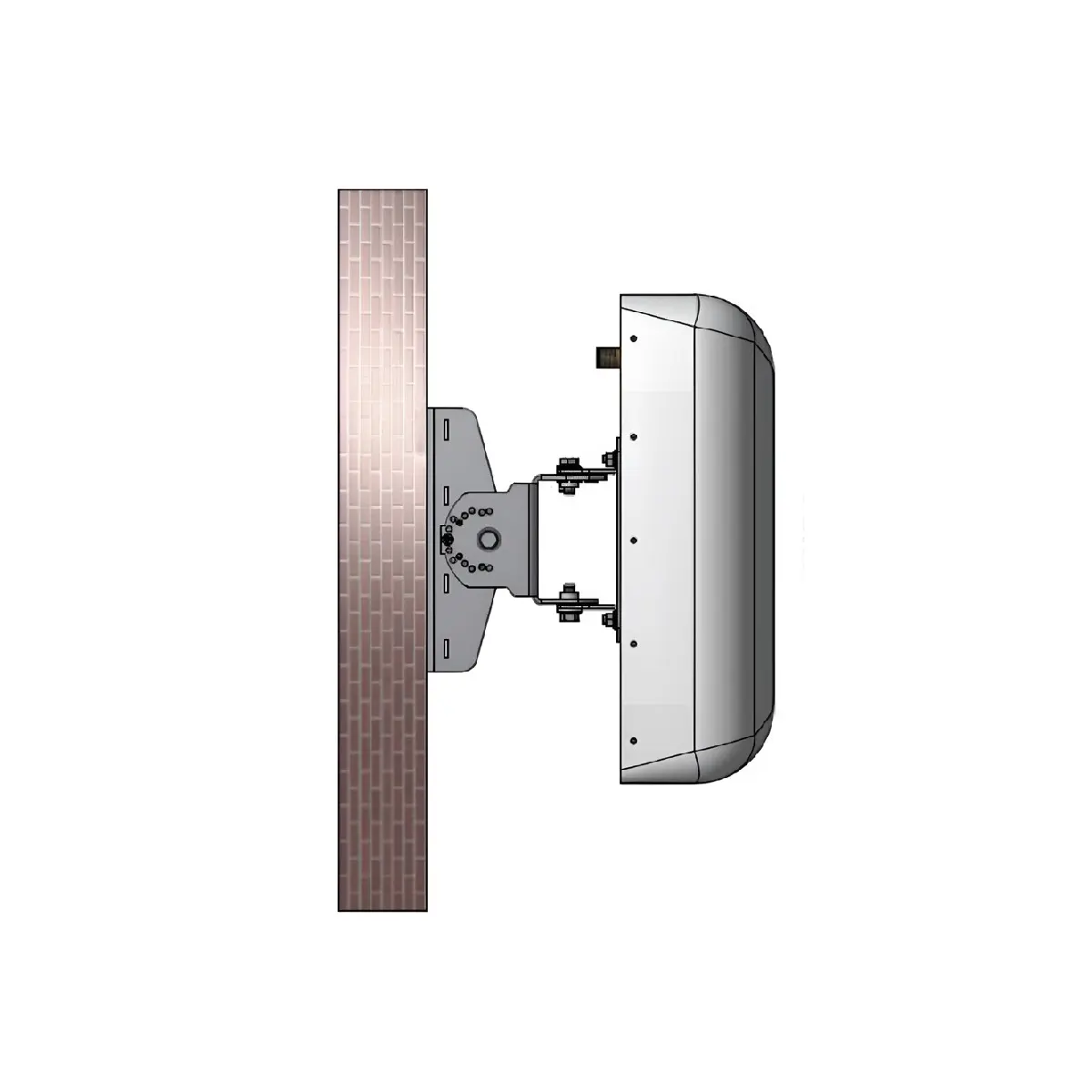

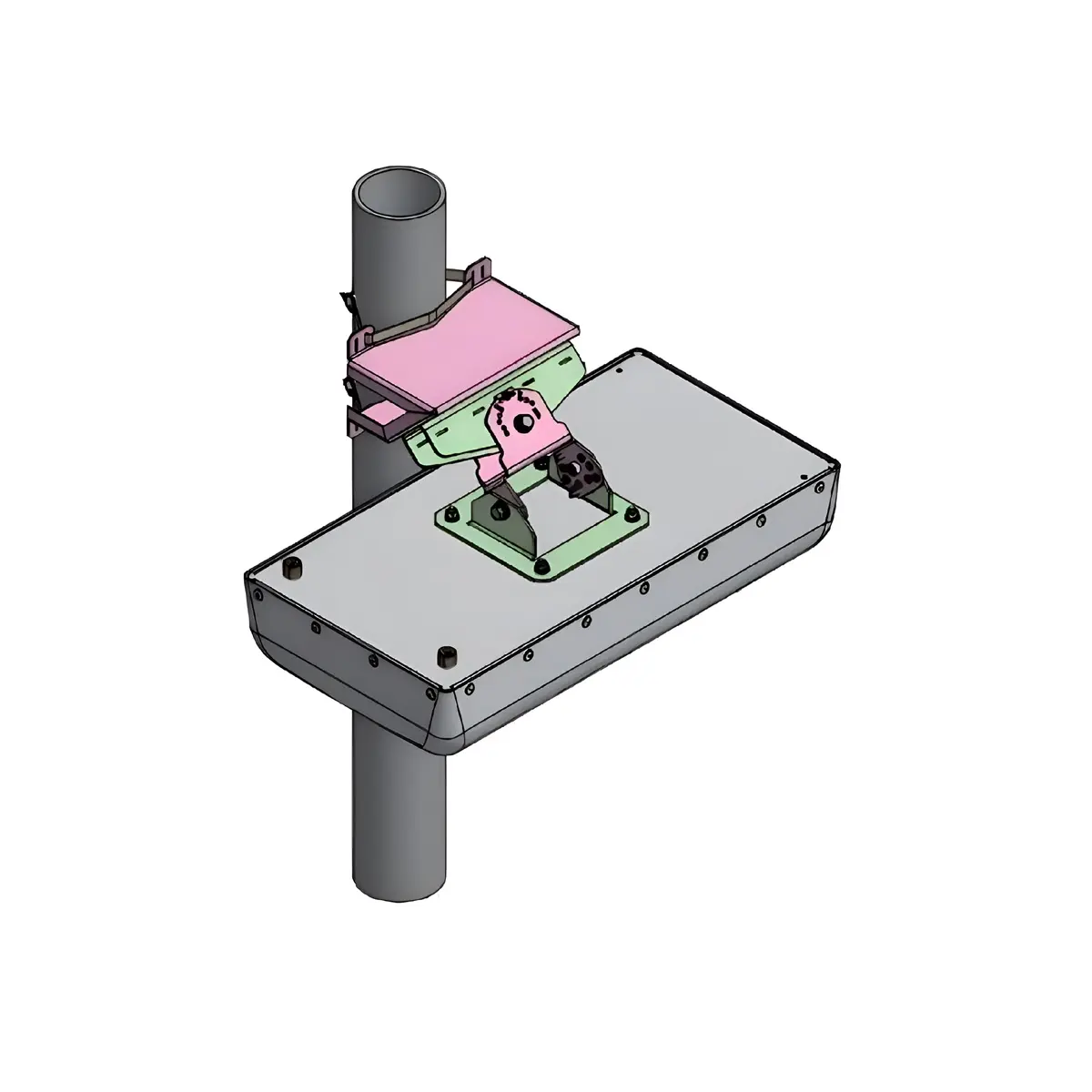

Stadium Antenna

JMA WirelessJul 2020 - Sep 2020I designed and developed custom stadium antennas for NFL stadiums to enhance wireless connectivity using SolidWorks and AutoCAD. I personally built 8 prototypes, out of which 4 are installed in the Dallas Cowboys stadium. After rigorous RF performance testing, I optimized the design for production using DFMA principles, leading to the manufacture of 120 antennas—4 for each of the 30 NFL stadiums. To meet the diverse mounting requirements of each stadium, I developed several sheet-metal brackets for versatile installation options, including ceilings, walls, poles, and over walls. This ensured each antenna met strict structural and performance standards, delivering reliable connectivity during games.

Stadium Antenna

Wall Mount

Pole Mount

- Product Development

- SolidWorks

- ANSYS

- GD&T

- DFMA

- Sheet Metal

-

Aircraft Design

University at BuffaloJan 2020 - May 2020I led the optimization of an aircraft model for enhanced flight performance by applying advanced aerodynamic and flight-dynamic principles. Utilizing SolidWorks and Creo Simulate, I meticulously refined the wing dimensions to maximize aerodynamic efficiency while maintaining structural integrity. I generated detailed technical drawings and developed a comprehensive Bill of Materials (BOM) to support the manufacturing process, ensuring precise implementation of design specifications. The project emphasized practical design solutions to achieve both performance and manufacturability in aerospace engineering.

- SolidWorks

- PTC Creo

- CFD

- Aerodynamics

-

Wind Turbine Analysis

University at BuffaloJan 2020 - May 2020I conducted a comprehensive safety analysis of wind turbines in Western New York, focusing on the risks of ice-throw and shadow-flicker effects in cold climates. Utilizing SolidWorks, MATLAB, and existing CFD simulation models, I assessed potential hazards and established minimum safety distances to protect residential areas. This project involved in-depth research, fluid dynamics simulations, and the application of engineering principles to enhance community safety. The findings provided actionable guidelines for turbine placement and risk mitigation to ensure safe and effective wind energy implementation in populated areas.

- SolidWorks

- MATLAB

- CFD

- Fluid Mechanics

-

La Laguna Water Sanitization

University at BuffaloJan 2019 - Dec 2019I developed a water treatment system for the coliform-heavy water supply in La Laguna, Nicaragua, as part of a project with Engineers Without Borders. Collaborating with a licensed Professional Engineer, I designed a catchment box in SolidWorks, incorporating filtration brackets to ensure clean drinking water. The project involved a comprehensive review of similar water sanitation efforts in Central America, planning the entire system, and applying effective filtration techniques to improve community health and sanitation. The system was engineered for long-term sustainability, leveraging local resources and enhancing the community's ability to maintain the system independently.

- SolidWorks

- CFD

- Fluid Mechanics

-

Game Based Learning

University at BuffaloAug 2018 - Dec 2018I developed educational games to supplement traditional learning methods, focusing on teaching fundamental engineering concepts like system dynamics. The project included creating a JavaScript-based game to simulate a mass-spring-damper system, which helped students understand natural frequency and damping ratios in an interactive, engaging format. By incorporating game mechanics, this project aimed to enhance student engagement and improve comprehension of complex engineering principles through practical, digital experiences.

- HTML

- JavaScript

- System Dynamics